XPRESS™

XPRESS™

4300

4300

1000

1000

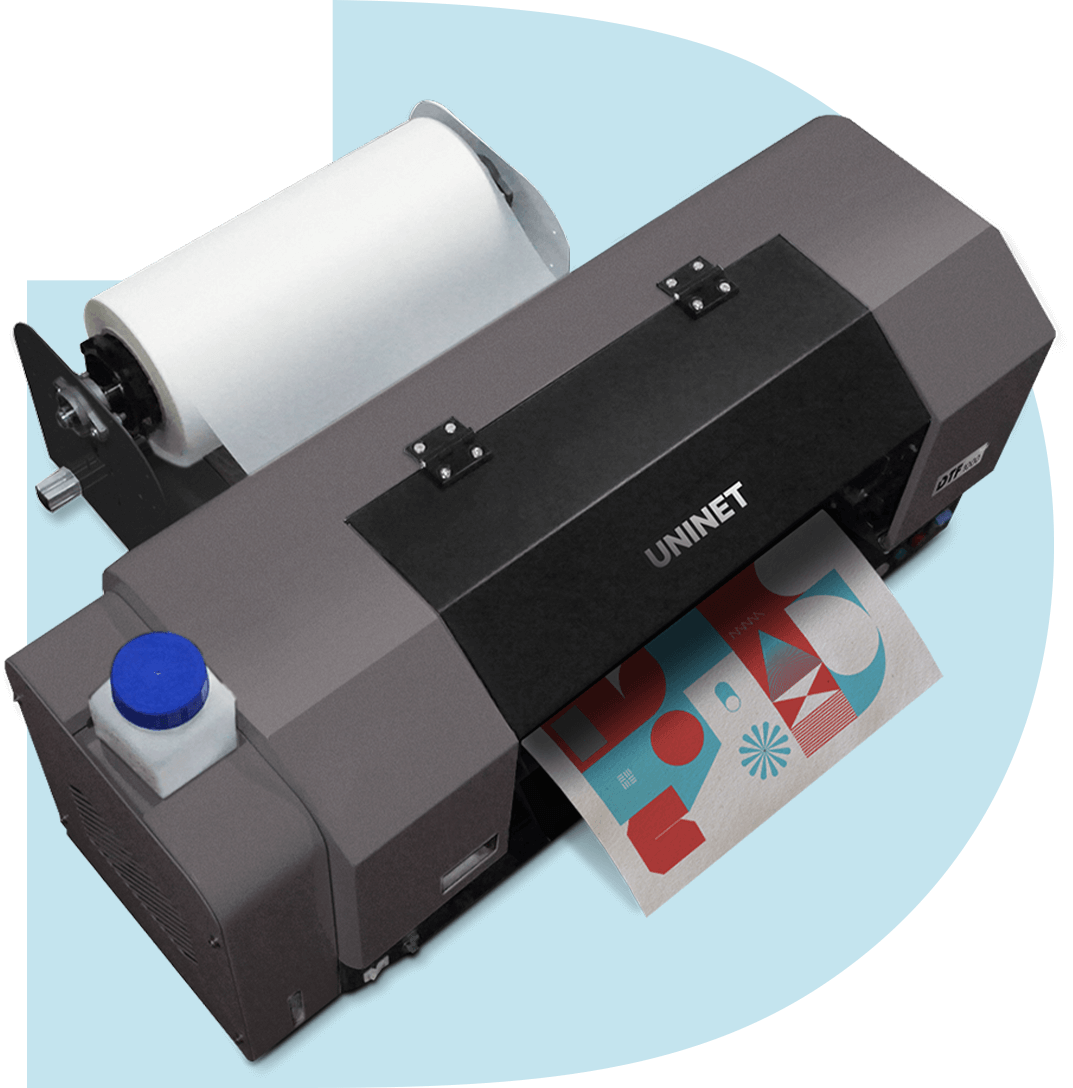

Ink-based label / sticker printer + built-in cutter,

all-in-one-solution on the market today.

Unleash Brilliance: Transforming the Label

Printing Industry with White Toner Revolution

Your business in a box: A digital color + white toner

printer for the transfer decoration industry.

The most versatile A3 Portable Tabloid Transfer Printer

with White Overprint and Underprint Capabilities available.

6000

6000

3000

3000